Photo etching:

a cost effective process, accurate and fast

a cost effective process, accurate and fast

How does chemical etching work?

During this process, an acid is used to dissolve the unprotected zones of the metal sheet in order to create a part with the expected shape. There are several stages:

Photo-tool

Prior to the process, a photo-tool is prepared. It is a transparent film on which the negative and accurate image of the part to manufacture is applied. Once it has been created, photo-tool can be used many times.

Surface preparation and coating

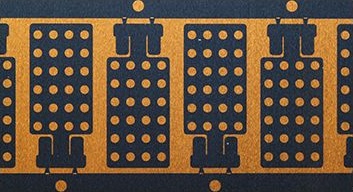

The metal sheet is first cleaned and a surface preparation is done (right side of the picture). It is then coated with a photo sensitive material (left side of the picture).

Insolation

The image of the part to manufacture is transferred by insolation through the photo-tool as a mask.

Developpement

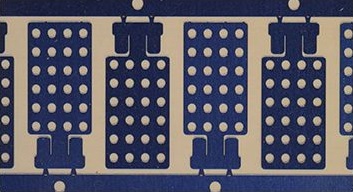

The development enables to wash away the photo sensitive coating that was protected from the insolation light by the non-transparent areas of the photo-tool, revealing the raw metal. Conversely, the photo sensitive coating exposed by light through the transparent areas of the photo-tool remains and protects the base material underneath.

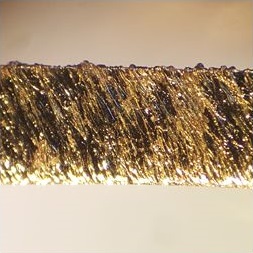

Chemical etching

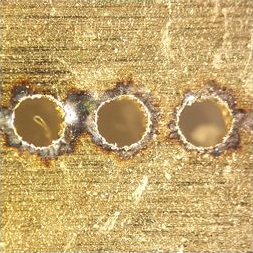

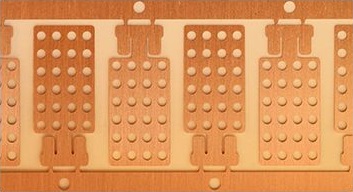

Chemical etching is performed on unprotected raw material, thus enabling to remove the metal all around the part and at its opening.

Stripping

Protective coating is then removed by stripping to get the completed part.

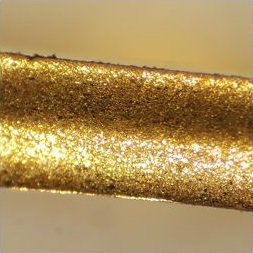

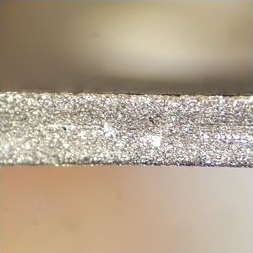

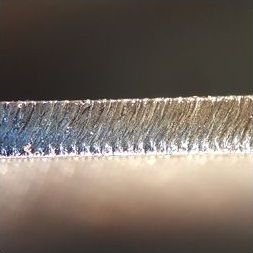

Chemical etching guarantees burrs and stress free, no breaking point and no heat-affected zone (HAZ). The internal structure of the material remains unchanged even at the cutting edge. This process, compatible with a wide range of materials, is particularly suitable for hard metal that is difficult to machine or for very thin parts.

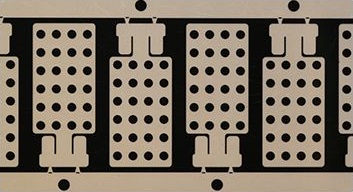

MECACHIMIQUE works with most of the metals and alloys in a thickness range from 0,01 up to 2 mm. Accuracy depends on the material and is proportional to its thickness.

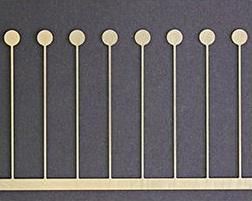

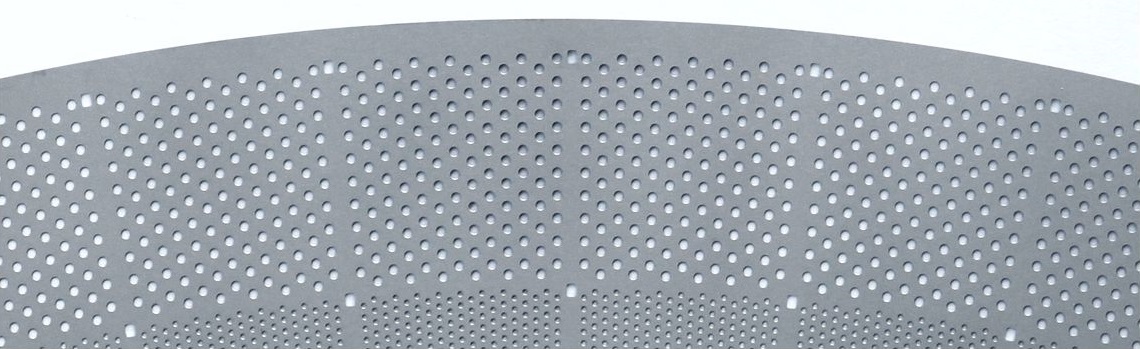

Etching enables to manufacture many different types of shapes. There is almost no limitation. And with partial etching the surface of the material can be engraved. Due to high versatility, combined with low cost and advantageous technical performances, chemical etching provides appropriate solutions for many types of applications.