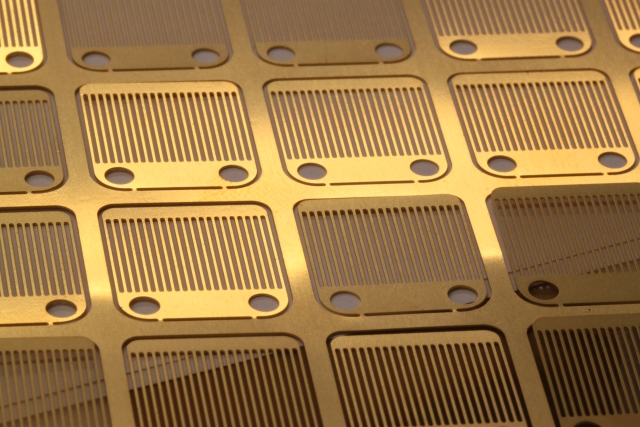

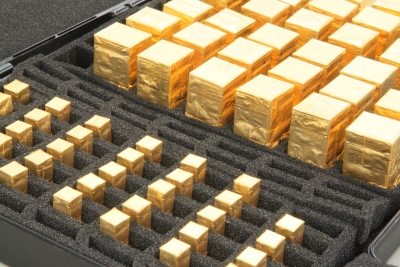

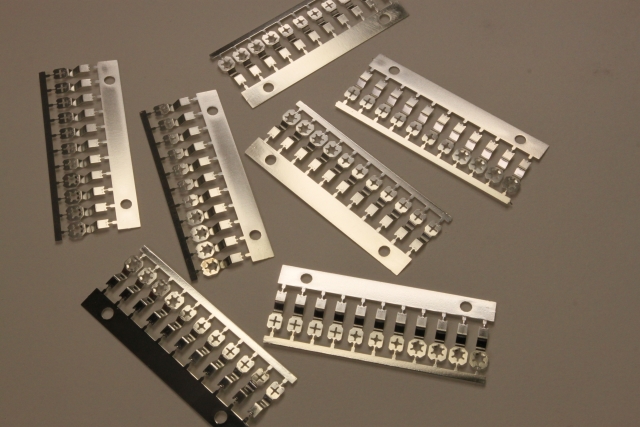

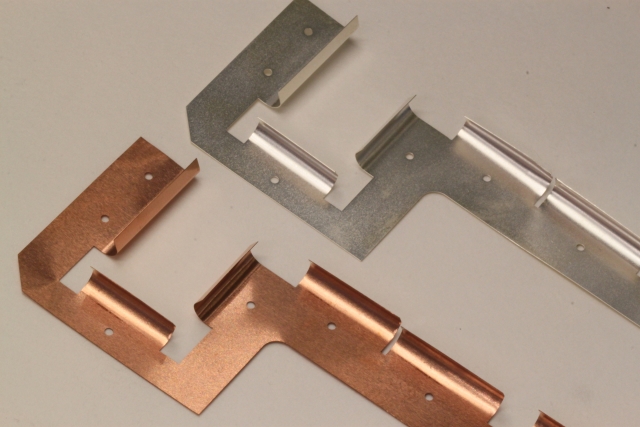

MECACHIMIQUE is specialized in three surface treatments:

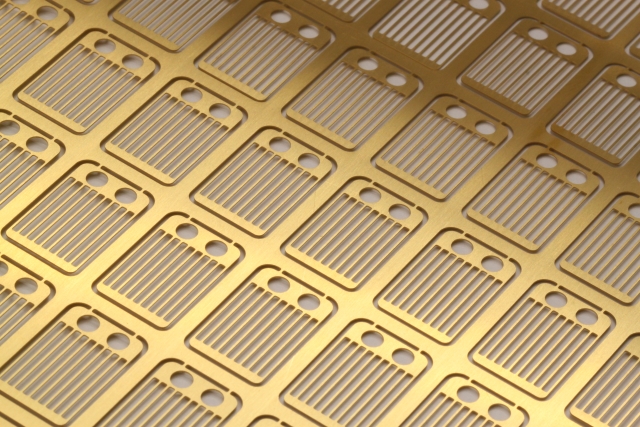

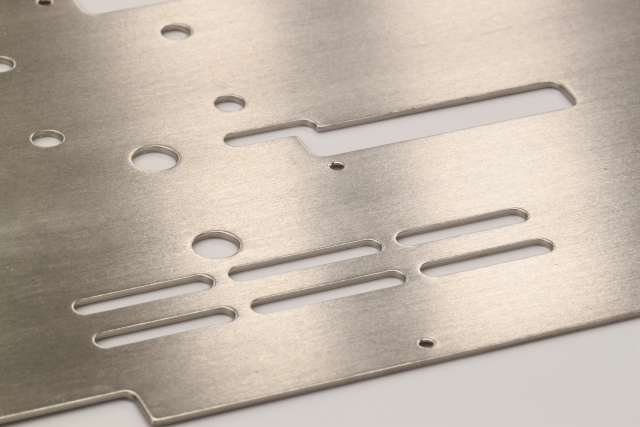

black coating – gilding – nickel plating

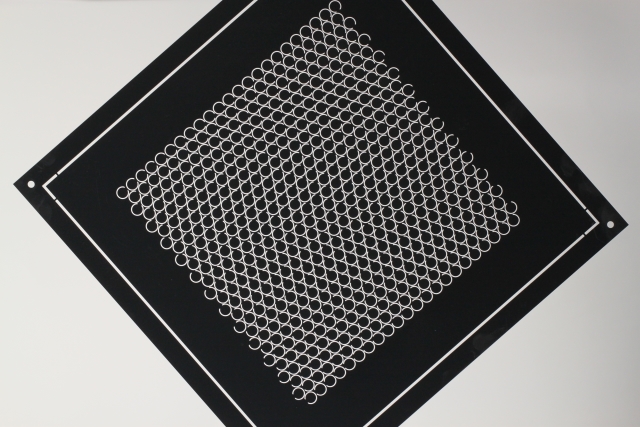

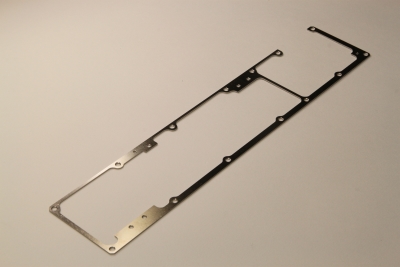

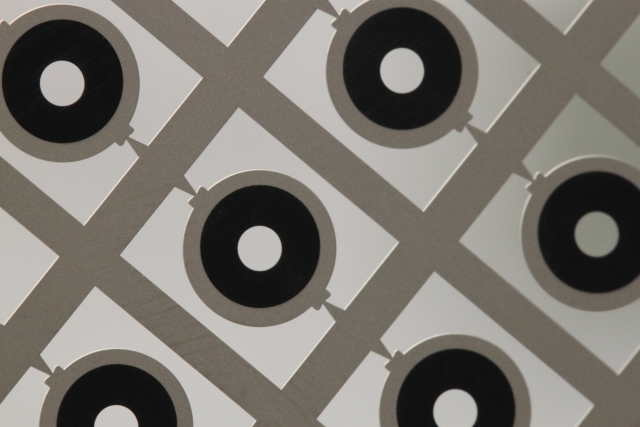

Anti-reflective black coating

or copper black oxide

The key features of our anti-reflective black coating

- Outstanding performance in the visible spectrum

- Hemispheric reflectance < 1,5%

- Certified for space, military and medical applications

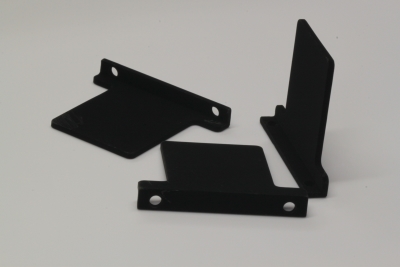

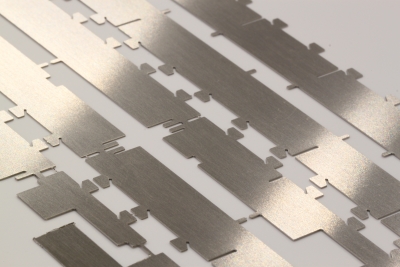

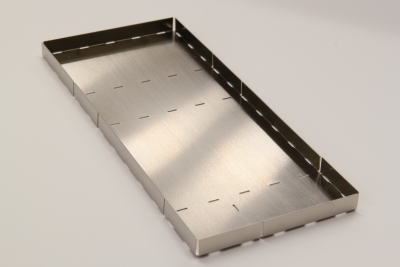

- Single- or double-sided treatment

- Compatible with selective masking