Specialist in photo chemical etching, electroforming and surface treatment. We use our experience and know-how to build your success.

Since 1972, MECACHIMIQUE has been specialised in photo chemical etching and electroforming for high precision metal parts manufacturing. We also achieve different surface treatments.

We are located next to Paris and collaborate with many different customers in a wide range of market sectors such as aerospace, electronics, defence, optical, medical and nuclear industries. We also supply the luxury, decoration and design branches.

Our internal R&D department is able to elaborate customized solutions in order to answer efficiently all your needs. Reactivity, punctuality and high end quality are our constant goals. We aim at your satisfaction.

News

MECACHIMIQUE has invested in an ISO 8 clean room for lamination and exposure operations.

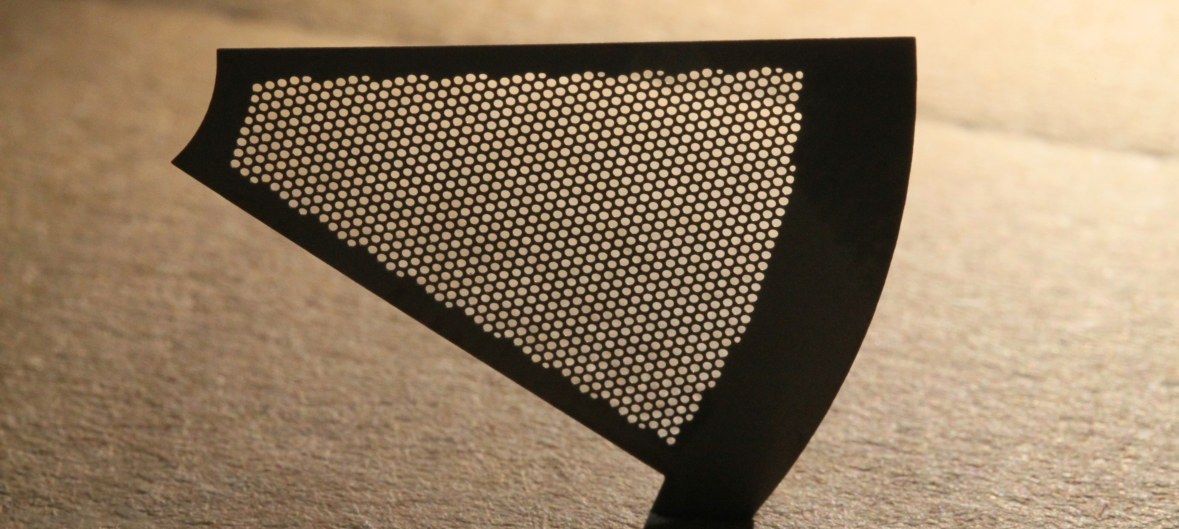

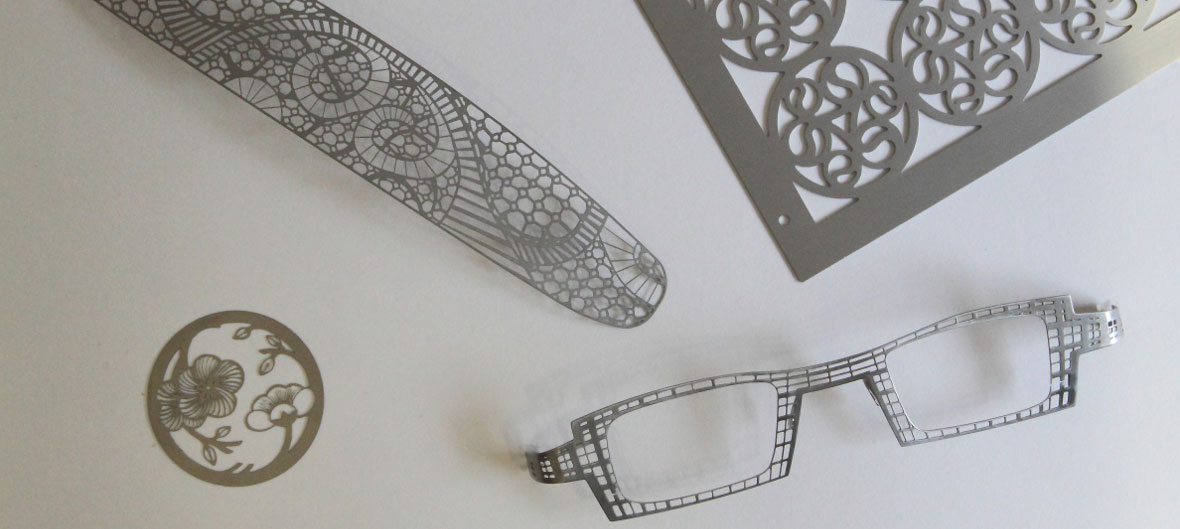

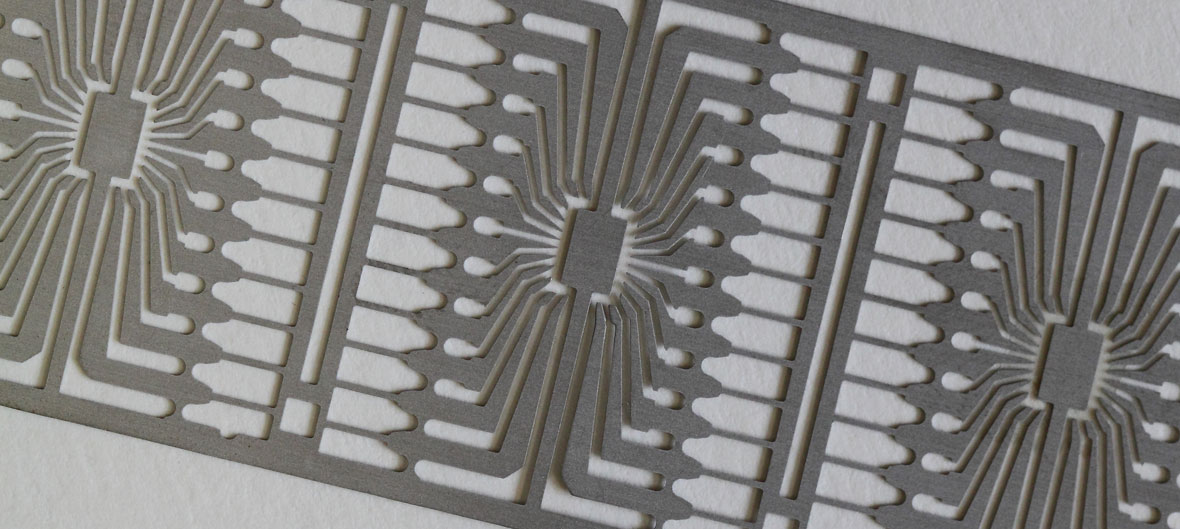

Photo Etching

Advantages of chemical etching process:

- Achieving complex shapes with tight tolerances for samples or series

- Unchanged base material's characteristics such as mechanical, electrical, and magnetic properties

- Burrs and stress free, no breaking point, no heat-affected zone

- Low tooling costs

- High flexibility in case of design modification

- Wide range of metals available in stock

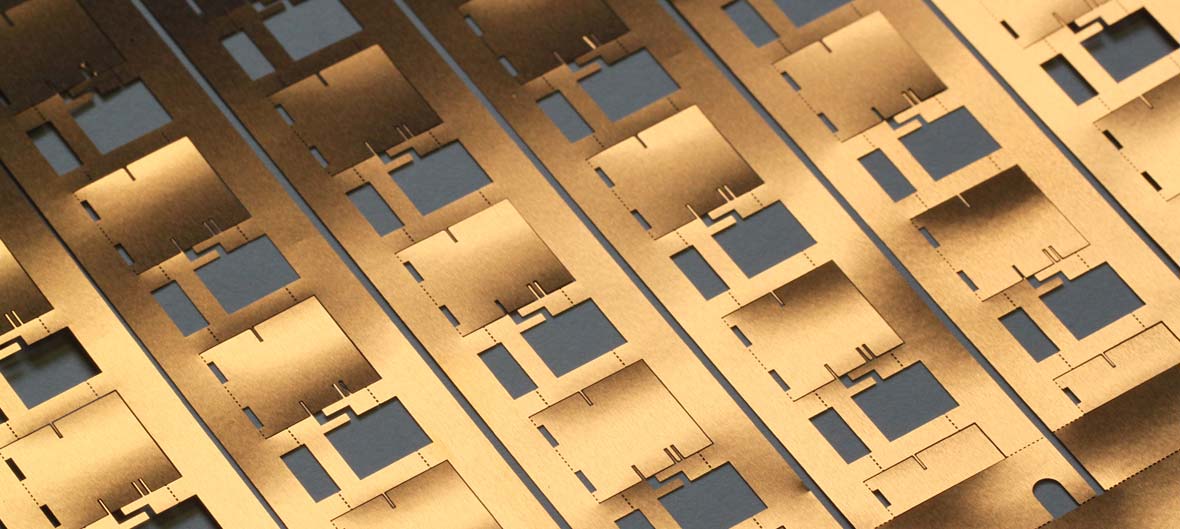

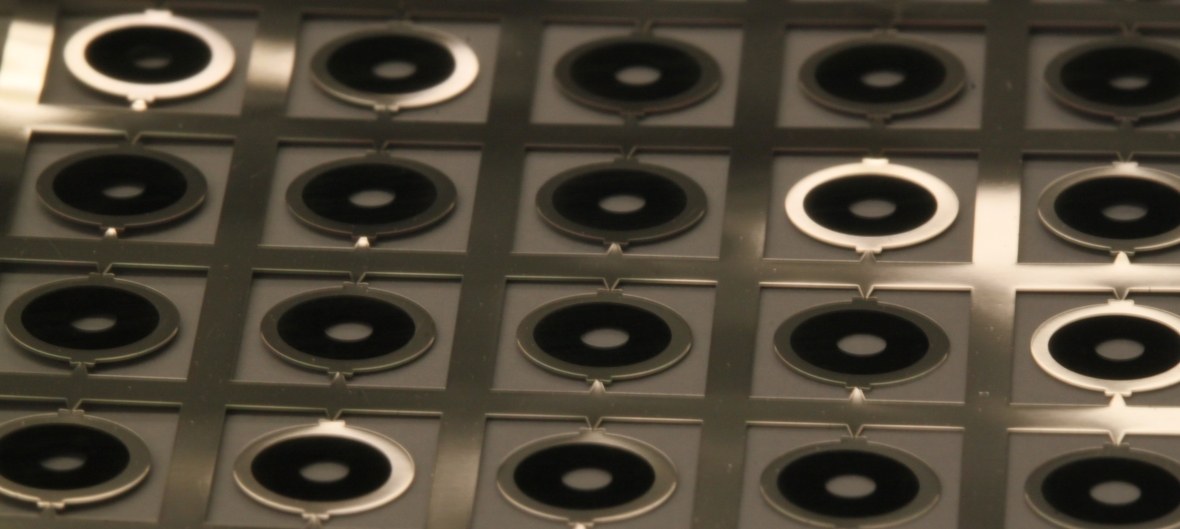

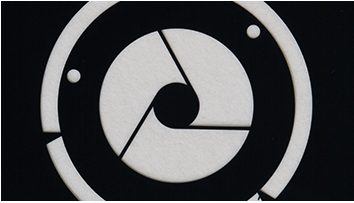

Electroforming

Advantages of electroforming process:

- Unrivalled micrometric precision

- Extremely complex shapes with very low thickness

- Very narrow aperture achievable

- Burrs and stress free, no breaking point, no heat-affected zone

- Low tooling costs

- Black surface treatment available, dedicated to optical applications

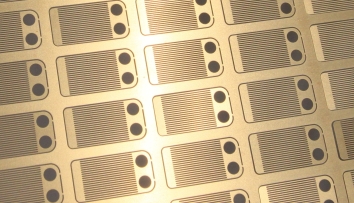

Surface treatment

Special features of our surface treatments:

- MECACHIMIQUE is specialized in three surface treatments: black coating – gilding – nickel plating

- Our black coating absorbs light reflection in the visible spectrum

- Our gilding and nickel-plating processes are approved by the European Space Agency (ESA).

- We provide a large range of other surface treatments performed by partner companies.

95,2%

on time

delivery

Punctuality

99,6%

product

conformity

Quality

72h max

to provide

a quotation

Reactivity

What our customers say about MECACHIMIQUE…

Chemical milling and electroforming:

two different processes suitable for a wide range of

applications

Click on the picture you are interested in to see examples of parts that we manufacture.